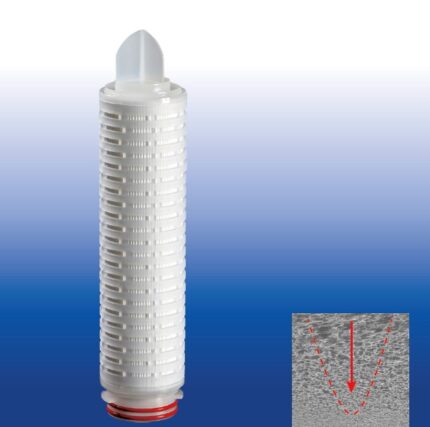

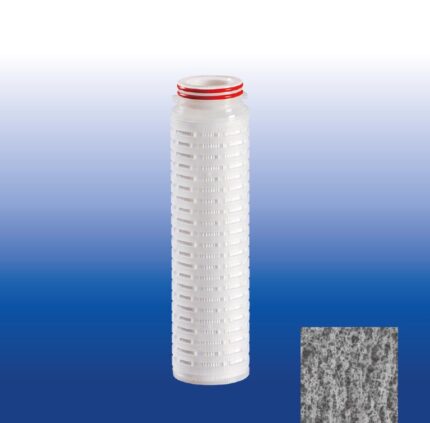

PTB Series Filter Cartridges feature hydrophobic polytetraflu-oroethylene (PTFE) membrane to provide excellent chemical compatibility with aggressive solvents, oxidizers, and corrosive fluids. 100% integrity tested for quality assurance.

Features

- Inherently hydrophobic PTFE membrane.

- Superior PTFE membrane grade offers highest degree of consistent performance.

- 100% integrity tested for correlation to absolute retention. Excellent chemical compatibility.

- Enhanced resistance to in-line steam sterilization and autoclaving.

Applications

- Chemically aggressive fluids.

- Solvents, strong acids & bases.

- Fermentation process air/gas filtration.

- Process air vents.

- Bulk gas.

Specifications

| Dimension | |

| Outer Diameter | 69mm (2.72”) |

| Lengths | 5”, 10”, 20”, 30”, 40” |

| Material of Constructions | |

| Media | Hydrophobic PTFE |

| Support Layer | Polypropylene |

| Cage/Core/End cap | Polypropylene |

| Seal Material Options | Silicone, EPDM, FKM |

| Performance | |

| Max. Operating Temperature | 80°C (176°F) |

| Max. Operating DP | 4 bar(58psi)@20°C(68F) 2 bar(29psi)@80°C(176F) |

| SIP | 135°C (275°F), 30 min, 150cycles |

| Filtration Area | 0.68 m² per 10” Filter |

| Pore Size | Gas: 0.01μm Liquid: 0.22μm |

Quality Assurance

- Validated with Brevundimonas diminuta (ATCC 19146) at107/cm2 (0.22μm).

- 100% Integrity Tested.

- Filter cartridges are manufactured in a clean room environ-ment using Good Manufacturing Practices under an ISO9001:2015 registered Quality Management System.

- Cartridges are individually serialized and have full materials traceability.

- Meets USP Biological Reactivity Test requirements of the current USP <88> for plastic class Ⅵ-121℃.

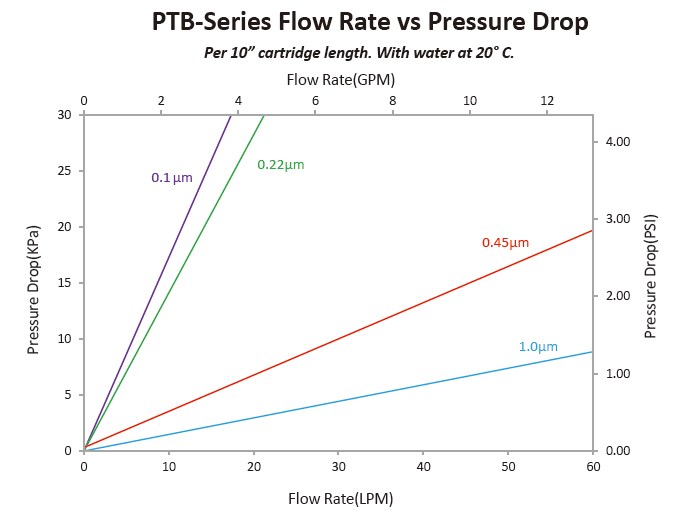

Flow Rate

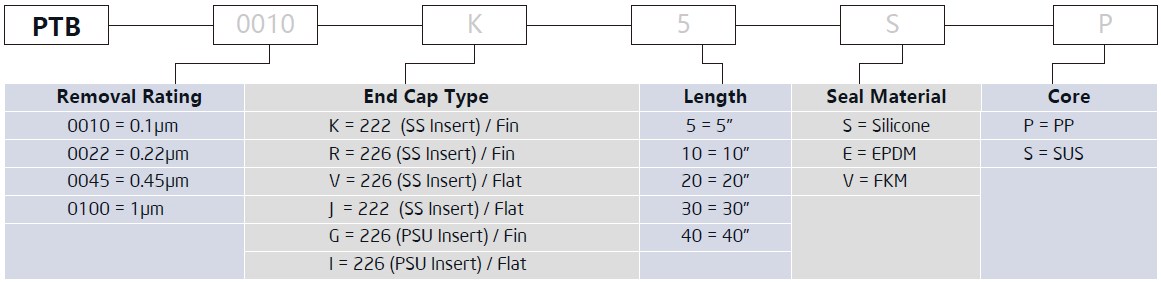

Order Information