HPTG Series Pleated Filter Cartridge is made of hydrophobic PTFE membrane, inherently hydrophobic PTFE membrane can ensure the sterilizing performance in different humidity environment. The oxidation resistant PP components offer superior oxidation and high temperature resistance. Reinforced core makes the filter cartridge higher pressure resistance, withstand in-line steam sterilization and autoclave, it is suitable for fermentation, pharmaceutical and other biotechnology applications.

Features

- Inherently hydrophobic PTFE membrane

- High temperature resistance

- Oxidation resistant hardware

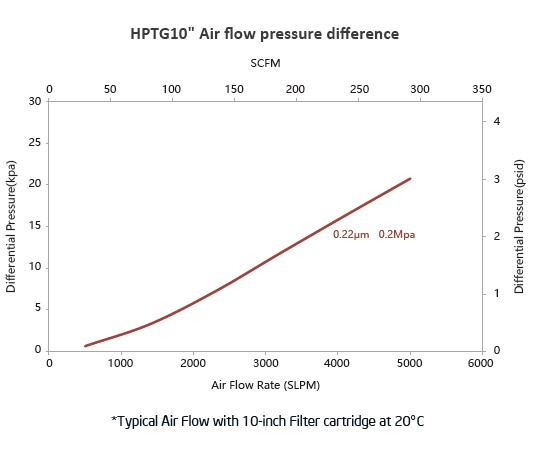

- High-flow and low pressure drop

- Enhanced steaming resistance

- 100% Integrity tested

Applications

- Process venting

- Compressed air

- Gas purification

- Fermentation feed air

Specifications

| Dimension | |

| Outer Diameter | 69mm (2.72”) |

| Lengths | 5”, 10”, 20”, 30”, 40” |

| Filtration Area | 0.68 m² per 10” Filter |

| Material of Constructions | |

| Media | Hydrophobic PTFE |

| Support Layer | PP/PET |

| Cage/End cap | High temperature resistance PP |

| Core | High temperature resistance PP/SS |

| Adapter | PP with insert |

| Pore Size | |

| Gas | 0.01μm |

| Liquid | 0.22μm |

| Performance | |

| Max. Operating Temperature | 100°C(212°F) |

| Max Operating DP | 5.2 bar (75 psi) @ 20°C (68°F) 2.4 bar (35 psi) @ 80°C (176°F) |

| SIP | 135°C(275°F), 30min, 150 cycles |

Quality Assurance

- Manufactured in a clean room environment.

- Manufactured according to ISO9001:2015 certified Quality Management System.

- Materials of construction comply with FDA requlations for food and beverage contact use as detailed in the US Code of Federal Regulations 21CFR.

- 100% Integrity Tested.

- Individual element is tracked by serial number.

Flow Rate

Integrity Test Parameters

| Bubble Point(BP) | 1100mbar(60/40 IPA/Water) |

| Water Instrusion(WIT) | HPTGP≤0.38ml/min@2500mbar HPTGW≤0.75ml/min@2500mbar |

Order Information