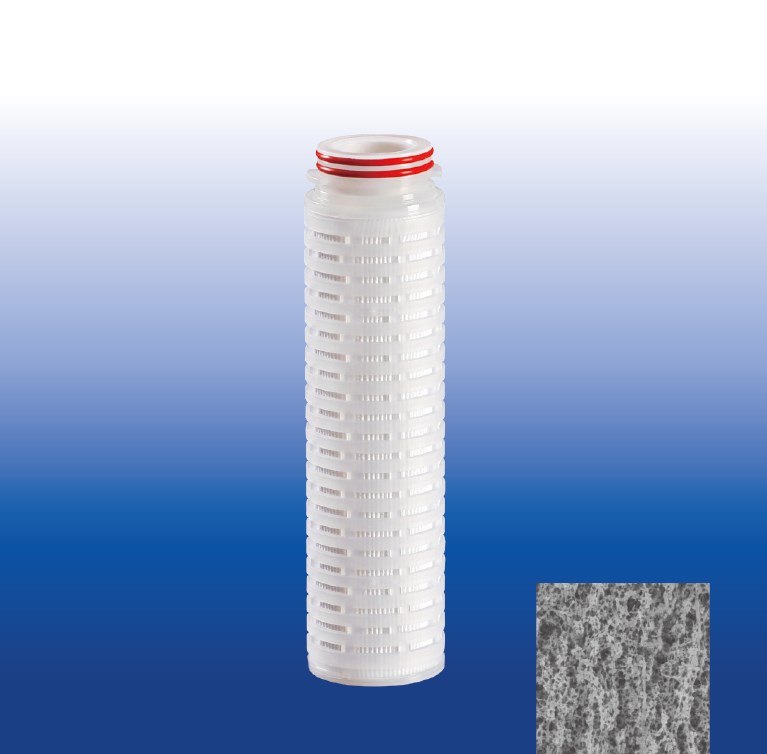

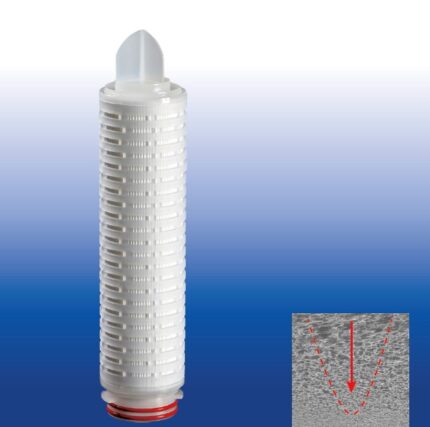

BDP series pleated filter cartridges feature hydrophilic polytetraflu-oroethylene (PTFE) membrane, which has wide chemical compatibili-ty and has been used for various kinds of acid and alkali, and oxida-tive solution filtration. It is good hydrophilicity and safe to use. BDP Series have passed biosafety and sterile challenge tests, and the bacteria removal is guaranteed.

Applications

- Corrosive reagent filtration

- Strong oxidizing liquid filtration

- Large infusion (LVP) sterile filtration

- Clarification filtration of organic solvents

- Large viscosity liquid filtration

- Eye drops sterile filtration

Features

- Good hydrophilicity, fast wetting

- Well-distributed membrane pore size

- High flux and dirt-holding capacity

- Resistance to corrosion, oxidation

- Excellent chemical compatibility

Specifications

| Dimension | |

| Outer Diameter | 69mm (2.72”) |

| Length | 5”, 10”, 20”, 30”, 40” |

| Materials of Construction | |

| Media | hydrophilic PTFE |

| Support | Polypropylene |

| Cage/Core/End cap | Polypropylene |

| Seal Material Options | Silicone, EPDM, FKM |

| Performance | |

| Operating Conditions | |

| Max.Operating Temperature | 80℃(176℉) |

| Max. Operating DP | 4 bar(58psi)@20℃(68℉) 2 bar(29psi)@80℃(176℉) |

| Sterilization | |

| Autoclave Sterilization | 125℃(257℉), 30min, 15cycles |

| SIP | 125℃(257℉), 30min, 15cycles |

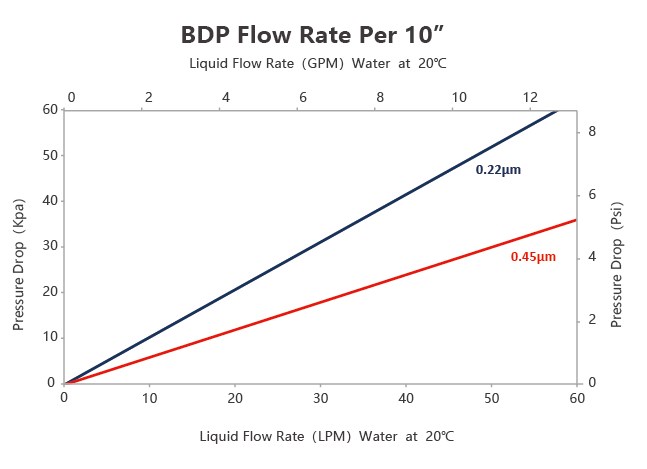

| Filtration Area | 0.65 m2 per 10” Filter |

| Extractables | |

| 10” Filter Cartridges | ﹤ 20mg |

Quality

- Manufactured in a clean room environment

- Manufactured according to ISO 9001:2015 certified quality

- management system Materials of construction comply with FDA regulations for food and beverage contact use as detailed in the US Code of Federal Regulations 21CFR

- Validated with Brevundimonas diminuta (ATCC 19146) at 107CFU/cm2 (0.22μm)

- 100% integrity tested

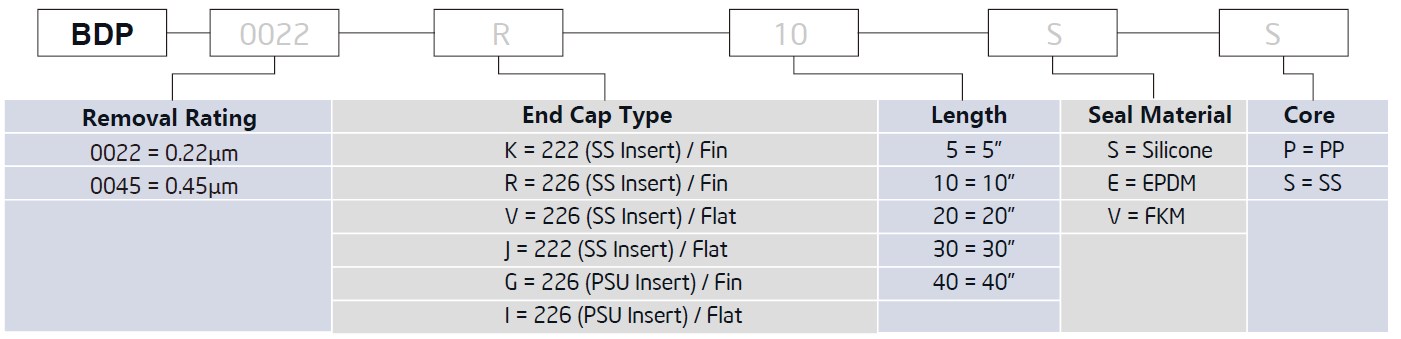

Order Information