PGA Series are all-polypropylene filter cartridges made with submicron fine fiber filter media which provide smaller pores. It is fabricated without using any binders, adhesives, plasti-cizers, and surfactants. PGA filters can be repeatedly hot water sanitized. The filter media and its support structure are thermally welded to the end caps, making integral filter cartridges of minimum extractables in a wide range of fluids and applications. All the filter cartridges are manufactured in a clean room environment.

Features

- Nominal rated structure, particle removal rating from 0.1 to 50 Micron

- Non filber release

- 100% polypropylene components provide broad chemical compatibility, suitable for use in a variety of fluids

- Various end cap configurations to fit into most standard housings

Applications

- Pharmacitical

- RO Pre-Filtration

- Fine Chemicals

- Process Water

Specifications

| Material of Constructions | |

| Media | Polypropylene |

| Support Layer | Polypropylene |

| Cage/End cap/Core | Polypropylene |

| Seal Material Options | Silicone, EPDM, NBR, FKM |

| Performance | |

| Max. Operating Temperature | 80℃(176℉) |

| Max Operating DP | 4 bar(58psi)@20℃(68℉) 2 bar(29psi)@80℃(176℉) |

| Filtration Area | 0.4 – 0.7m2 per 10” Filter |

Quality Assurance

- Manufactured in a clean room environment

- Manufactured according to ISO9001:2015 certified Quality Management System

Food Contact Compliance

- Materials of construction comply with FDA regulations for food and beverage contact use as detailed in the US Code of Federal Regulations 21CFR

- Passed European Commission Directives (EU10/2011)

- Halal Certified

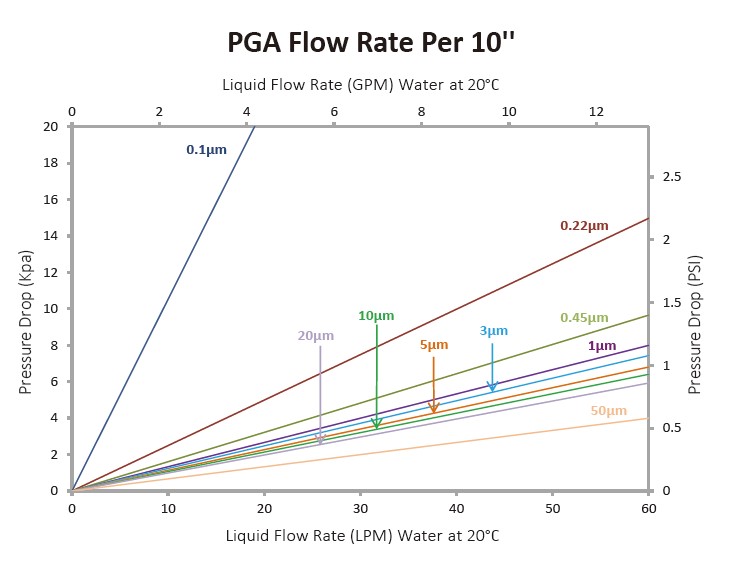

Flow Rate

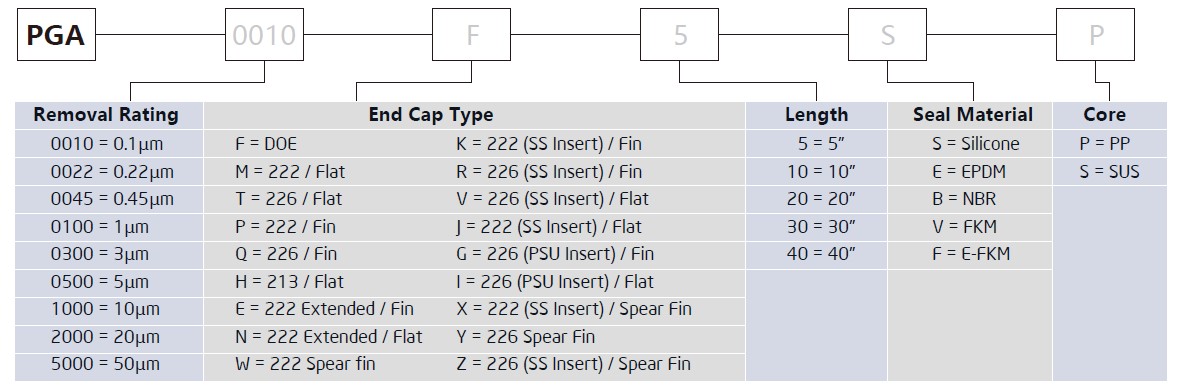

Order Information