STH Series Hydrophobic PTFE filter cartridges are constructed of hydrophobic PTFE membrane and polypropylene supports to provide the greatest assurance of filtration performance and chemical compatibility in severe process conditions. The highly porous PTFE membrane offers high flow rates and long service life.

Features

- PTFE and polypropylene components provide extremely wide chemical compatibility

- Contains no binders or adhesives for wide solvent compati-bility with extremely low extractables

- Fully integrity testable for assured product integrity and effectiveness in operation

- 100% integrity testing during manufacture guarantees product reliability and consistency

Applications

- Pharmaceutical

- @Vents

- @Filtration of Compressed Gases

- @Filtration of Solvents

- Food and Beverage

- @Sterile Venting of Holding Tanks

- @Sterile CO2 Filtration

- @Microbial Control of Inlet

- @Air for Bioprocessing of Foods

- Process Gases

- @Bulk and Point-of-Use Gases

- @Compressed Air

- Chemicals

- @ Solvents

- @Bulk Filling

- @Acids

Specifications

| Dimension | |

| Outer Diameter | 69mm (2.72”) |

| Lengths | 5”, 10”, 20”, 30”, 40” |

| Material of Constructions | |

| Media | PTFE |

| Support Layer | Polypropylene |

| Hardware | Polypropylene |

| Seal Material Options | Silicone, EPDM, NBR, FKM, E-FKM |

| Performance | |

| Max. Operating Temperature | 80℃(176℉) |

| Max.Operating DP | 4 bar (58 psi) @ 20°C (68°F) 2 bar (29 psi)@ 120℃(248°F) |

| SIP | 125℃ (275° F), 30min, 30 Cycles |

Quality Assurance

- Manufactured in a clean room environment Manufactured according to ISO9001:2015 certified Quality Management System

- 100% Integrity Tested

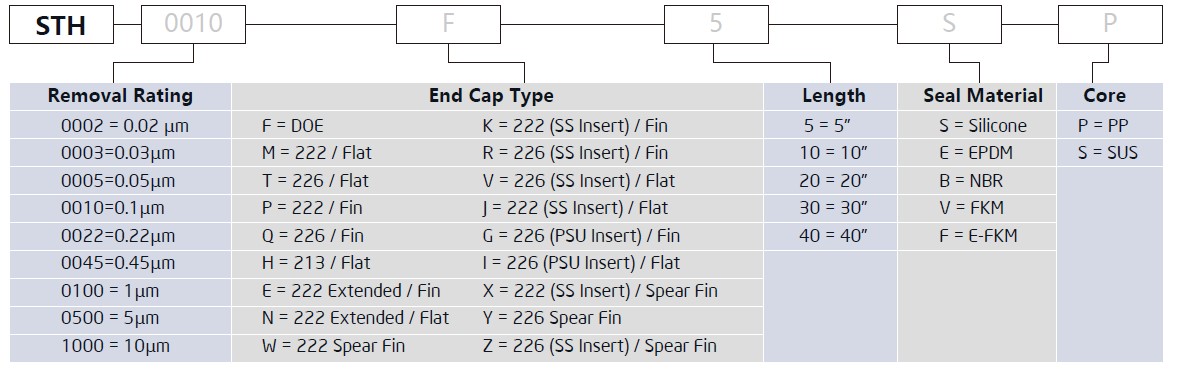

Order Information